7. Example of a variable stiffness plate in compression#

Load tutorial into dapta app.

View files on Github.

Duration: 60 min

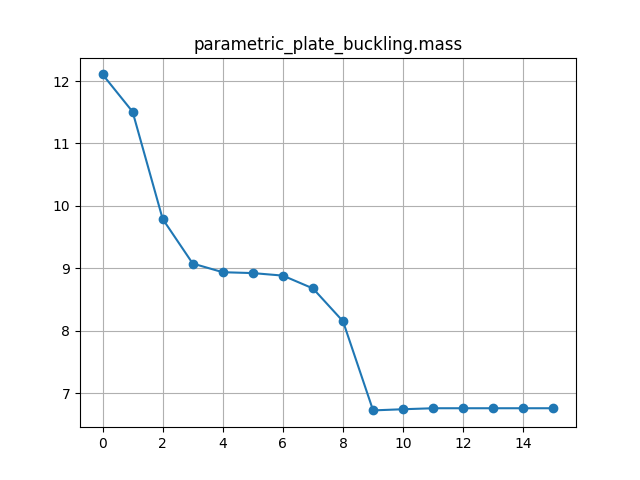

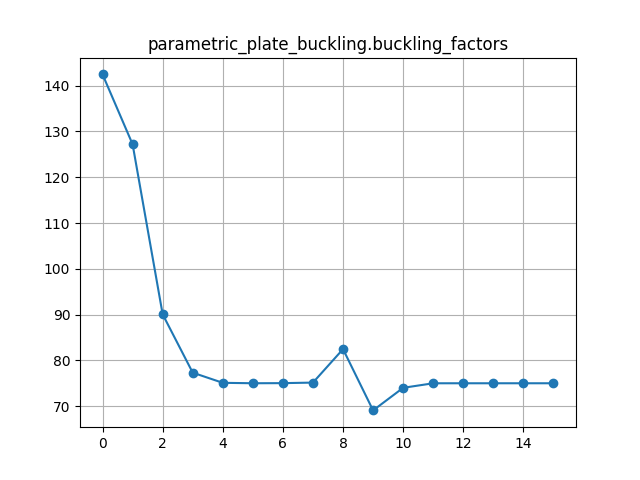

We optimise the design of a variable stiffness RTS composite plate in compression. We use CalculiX to model the plate and analyse the buckling behaviour, and OpenMDAO to minimise the mass of the plate, subject to a minimum buckling load constraint.

This example is based on Reference 1 and results are compared to the reference data showing a good correlation.

7.1. Model overview#

7.1.1. Variable stiffness RTS composites#

With steered-fibre composites (also called variable-stiffness composites), engineers have the option to change the fibre directions within each ply, as well as stacking plies with different fibre orientations through the laminate thickness.

The use of steered-fibre composites opens-up the design space and has been shown to lead to lighter, more efficient designs in a number of applications, for example, by steering fibres around holes or cut-outs in complex parts [2]. By steering the fibres, the number of stacked plies and their surface area can be optimised for structural efficiency, which leads to lighter designs. The use of fewer plies and the increased control over ply shapes has another benefit: it could speed-up the manufacturing process and reduce material wastage.

Rapid tow shearing (RTS) is a new patented manufacturing method for steered-fibre composites that is being developed by iCOMAT (icomat.co.uk). One of the main benefits of RTS is that the fibres can be steered to a tight radius (50mm), without generating fibre wrinkling, gaps or overlaps, which are defects that can significantly compromise the structural performance. This is a key advantage compared to other steering methods, such as ATL, AFP or TFP.

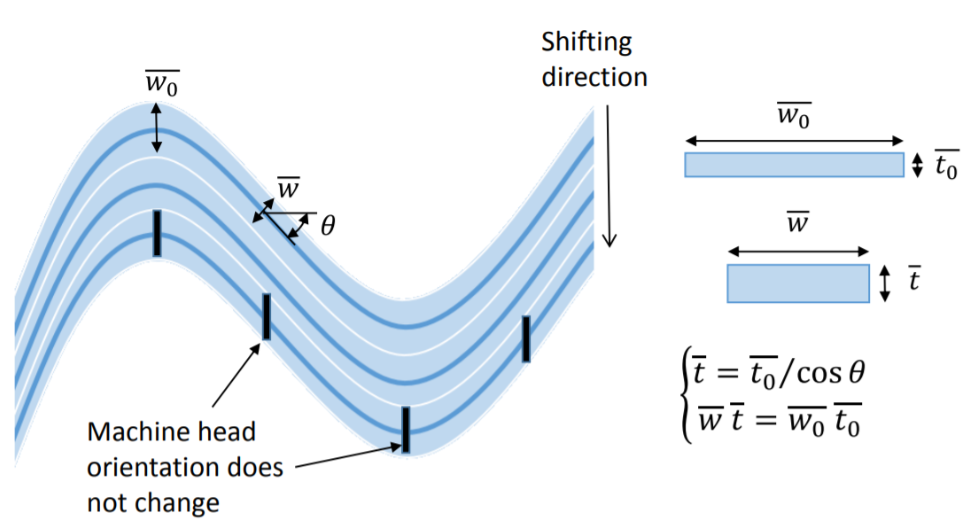

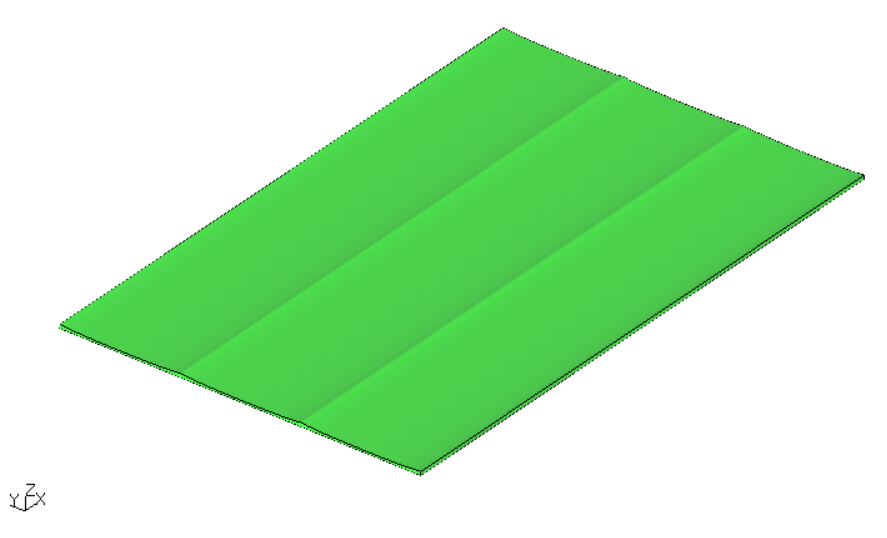

With RTS the thickness of the ply changes as a function of the steering angle (or more precisely “shearing”-angle) as shown in the figure below. This means that thickened laminate regions can be introduced purely by locally shearing the fibres, potentially removing the need to add plies near joints or other high stress areas.

7.1.2. Modelling approach in Calculix#

Our objective is to optimise an RTS composite plate design for minimum mass, subject to a minimum buckling load constraint and to compare our results with data from Reference 1. We reduce the size of the optimisation problem compared to Reference 1 by using a fixed composite ply stacking sequence and only optimising the outer RTS ply steering angles.

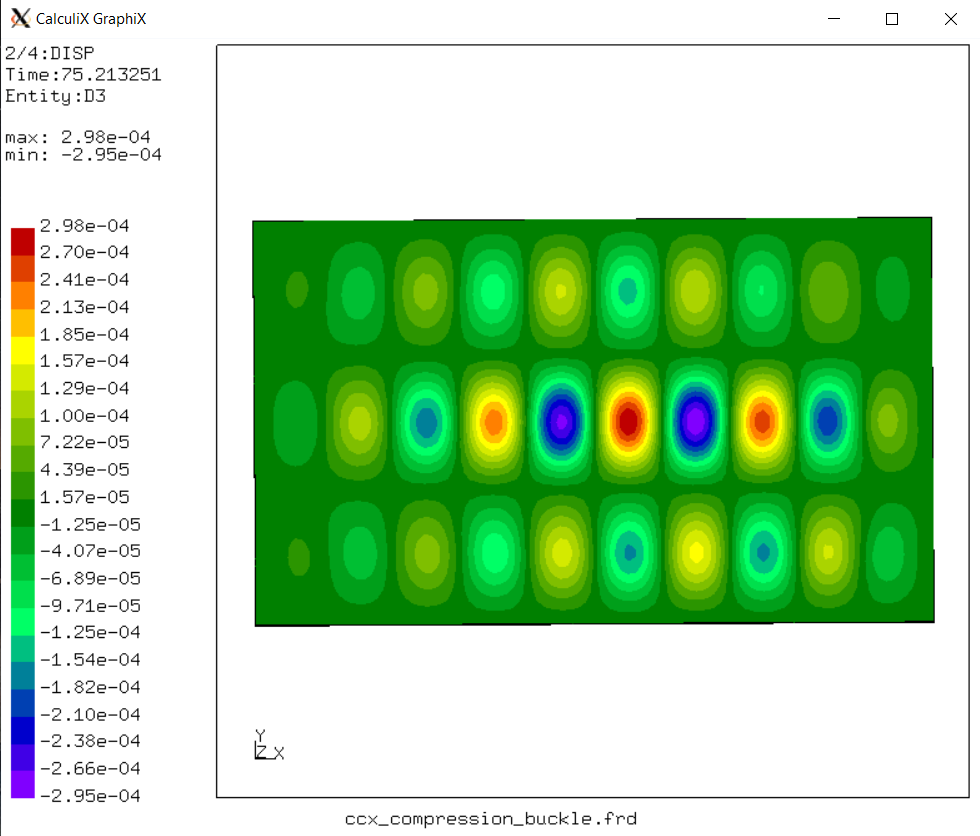

We create a parametric Calculix finite element model of the plate to perform a linear eigenvalue buckling analysis. This type of analysis can be used to estimate the critical (bifurcation) loads of “stiff” structures.

7.1.2.1. Modelling the boundary conditions#

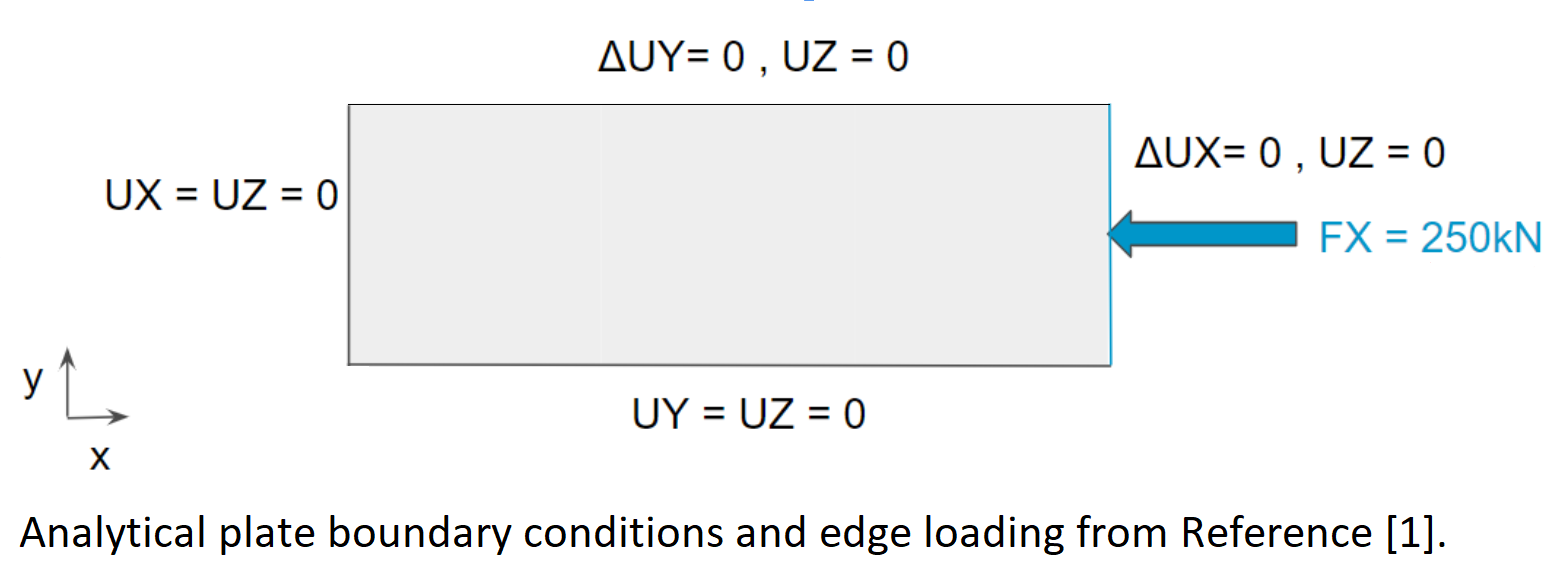

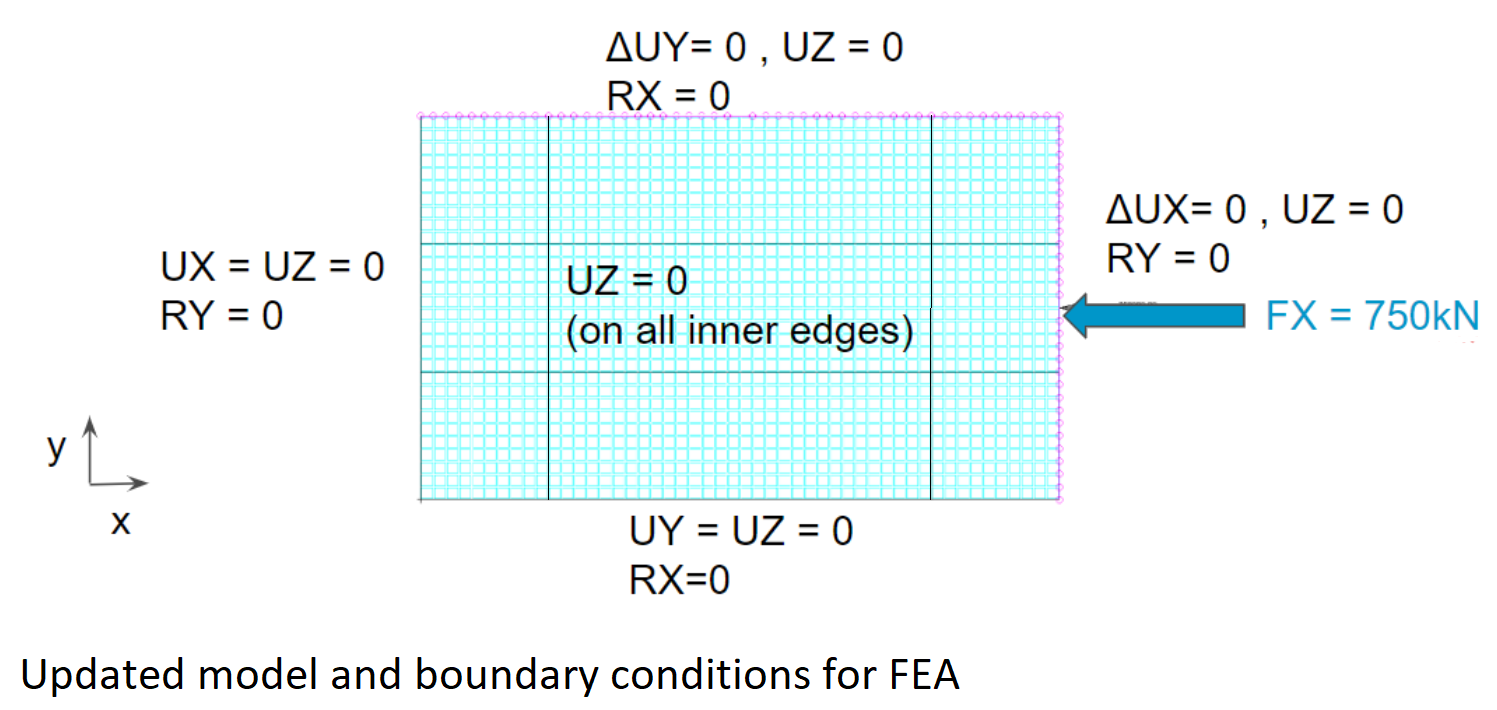

The rectangular plate (250x750mm) described in the reference is simply supported on all edges and loaded in the x-direction as shown below. In the reference, the analytical boundary conditions are applied directly at the laminate neutral plane, the location of which is a function of the laminate properties. There is normally no requirement for element nodes to coincide with the laminate neutral plane. Therefore, it may be difficult to reproduce these boundary conditions in a finite element model - particularly with shell elements. Instead we will be using a 5x larger model (750mmx1250mm) and boundary conditions shown in the second figure. This allows us to model boundary conditions on the 250x750mm inner plate that closely resemble simply supported conditions.

Note

For a constant stiffness panel, we could have reduced the size of the model by assuming symmetric boundary conditions in the x and y directions. However, the plate’s stiffness distributions here are not necessarily symmetric depending on the control point locations and fibre angle values.

7.1.2.2. Modelling the applied compression load#

The compression load (750kN) shown in the second figure is the target load below which the panel should not buckle. The compression load is applied to the model via a kinematic coupling (using the *KINEMATIC keyword), which distributes the load to the edge nodes and ensures that the edge remains straight. A second kinematic coupling is applied to the top edge of the plate to keep it straight, whilst allowing nodes to slide in the x and y directions.

Warning

We actually apply a lower load (10kN) to the model in Calculix Crunchix and constraint the minimum buckling factor to 75.0 in the OpenMDAO driver parameters. This ensures that the compression load applied to the model is always lower than the expected buckling load factor during the design optimisation iterations, without which the solver may return erroneous buckling load factors. We also request the first 10 buckling modes as an output with the *BUCKLE keyword, to ensure that the lowest mode is calculated with sufficient accuracy.

7.1.2.3. Defining the design variables#

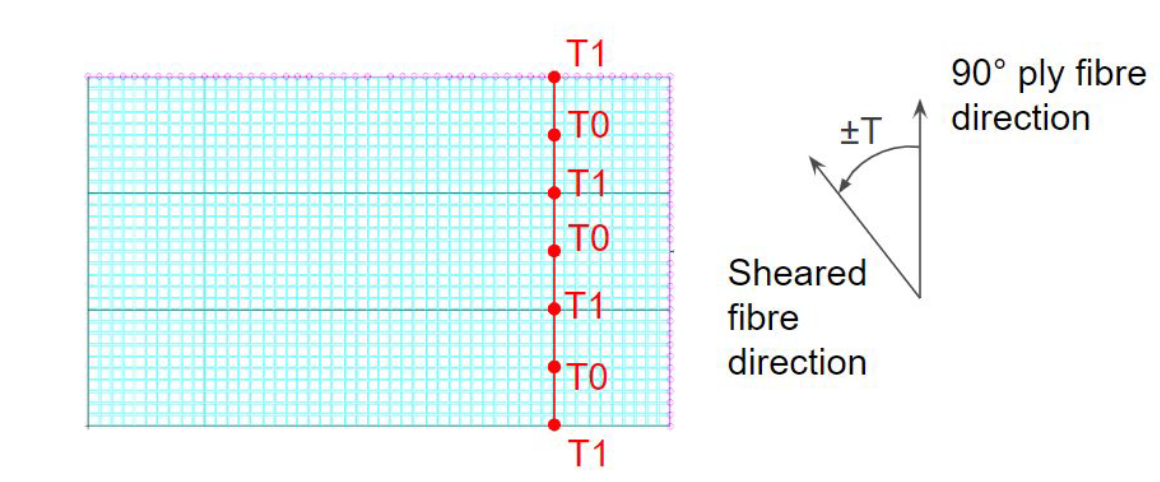

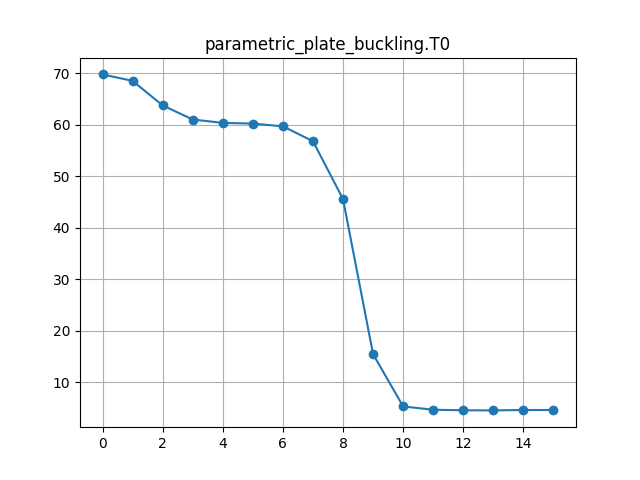

The design variables for the RTS panel are the outer ply shearing angles T0 and T1, which are defined at 7 equally spaced control points in the 90 degree ply reference direction (model y-direction) as shown in the next figure. The location of the control points is also a variable in the component parameters, but we will not change these positions in this example.

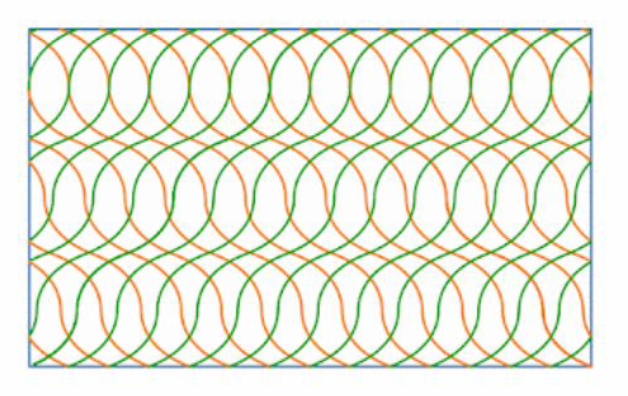

For example, by defining angles of 0 and 69 degrees at T0 and T1 respectively, we can now model the fibre paths shown below in green and orange for the +/- RTS plies. Note that the plate lower surface is flat, so that the thickness variation shown below due to the fibre shearing is only visible on the upper surface.

7.1.2.4. Choosing the element type#

We choose to model the plate directly with solid C3D20R elements, as the alternative of using S8R shell elements with varying thicknesses in CalculiX would introduce undesired rigid body constraints at element interfaces [3]. To reduce the number of elements through the thickness of the plate, we also choose to calculate homogenised material properties for +/- plies, so that the optimal 28-ply RTS laminate design \([(90 \pm \langle 0|69 \rangle)_4 / 90 \pm \langle 0|67 \rangle / \pm 80 / 90_2]_s\) from Reference 1 can be approximated with only 3 element layers consisting of the following sub-laminates: \([(90 \pm \langle 0|69 \rangle)_5]\), \([90_8]\) and \([(90 \pm \langle 0|69 \rangle)_5]\).

7.2. Automating the design optimisation#

7.2.1. Load a workflow from file#

Copy the JSON object below into a text editor and save it locally, then select Open to load it.

Two components should appear in the workspace.

Since the second component is a driver we do not define any connections between components in this workflow.

dapta_input.json

{

"components": [

{

"name": "parametric-plate-buckling",

"api": "calculix-fea-comp:latest",

"options": {},

"parameters": {

"length_x": 1.250,

"width_y": 0.75,

"split_at_x": [

0.25,

1.0

],

"split_at_y": [

0.25,

0.5

],

"boundary_conditions": {

"fixed_y0": {

"lines": [

0,

1,

2

],

"SPC": "23"

},

"fixed_x0": {

"lines": [

9,

10,

11

],

"SPC": "13"

},

"support_z": {

"lines": [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23

],

"SPC": "3"

},

"support_ymax": {

"lines": [

6,

7,

8

],

"kinematic": "23",

"ref_node_SPC": "3456",

"surface_vector": [

0.0,

1.0,

0.0

]

},

"loaded_xmax": {

"lines": [

3,

4,

5

],

"kinematic": "13",

"ref_node_SPC": "3456",

"surface_vector": [

1.0,

0.0,

0.0

],

"ref_node_forces": [

-10000.0,

0.0,

0.0

]

}

},

"edge_length": 0.025,

"material": {

"E1": 163.0e9,

"E2": 12.0e9,

"nu12": 0.3,

"G12": 5.0e9,

"thickness": 0.000125,

"density": 1571.0,

"tape_width": 0.100,

"stress_allowables": {},

"name": "IM7_8552",

"description": " Units are: kg, m; data from Groh_2015."

},

"plies": [

{

"path_start": [

0,

0,

0

],

"path_end": [

0,

0.750,

0

],

"ply_ref_angle": 90.0,

"ply_ref_thickness_multiplier": 10,

"combine_plus_minus_plies": true,

"control_pts": [

{

"d": -0.01,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.000,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.125,

"inc_angle": 0.0,

"id": "T0"

},

{

"d": 0.250,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.375,

"inc_angle": 0.0,

"id": "T0"

},

{

"d": 0.500,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.625,

"inc_angle": 0.0,

"id": "T0"

},

{

"d": 0.750,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.760,

"inc_angle": 69.0,

"id": "T1"

}

]

},

{

"path_start": [

0,

0,

0

],

"path_end": [

0,

0.750,

0

],

"ply_ref_angle": 90.0,

"ply_ref_thickness_multiplier": 8,

"combine_plus_minus_plies": true,

"control_pts": [

{

"d": -0.01,

"inc_angle": 0.0

},

{

"d": 0.760,

"inc_angle": 0.0

}

]

},

{

"path_start": [

0,

0,

0

],

"path_end": [

0,

0.750,

0

],

"ply_ref_angle": 90.0,

"ply_ref_thickness_multiplier": 10,

"combine_plus_minus_plies": true,

"control_pts": [

{

"d": -0.01,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.000,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.125,

"inc_angle": 0.0,

"id": "T0"

},

{

"d": 0.250,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.375,

"inc_angle": 0.0,

"id": "T0"

},

{

"d": 0.500,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.625,

"inc_angle": 0.0,

"id": "T0"

},

{

"d": 0.750,

"inc_angle": 69.0,

"id": "T1"

},

{

"d": 0.760,

"inc_angle": 69.0,

"id": "T1"

}

]

}

],

"mesh_files": {

"mesh": "all.msh",

"solid_mesh": "solid_mesh.inp",

"materials": "materials.inp",

"element_sets": "element_sets.inp",

"solid_sections": "solid_sections.inp",

"node_sets": "node_sets.inp",

"surfaces": "surfaces.inp",

"constraints": "constraints.inp",

"loads": "loads.inp"

},

"analysis_file": "ccx_compression_buckle.inp",

"number_of_modes": 10

},

"inputs": {

"T0": 70.0,

"T1": 70.0

},

"outputs": {

"mass": 0.0,

"buckling_factors": [

0.0

]

}

},

{

"name": "open-mdao",

"api": "generic-python3-driver:latest",

"options": {},

"parameters": {

"user_input_files": [],

"optimizer": "SLSQP",

"max_iter": 20,

"tol": 1e-6,

"disp": true,

"debug_print": [

"desvars",

"ln_cons",

"nl_cons",

"objs",

"totals"

],

"approx_totals": true,

"fd_step": 0.2,

"input_variables": [

{

"component": "parametric-plate-buckling",

"name": "T0",

"lower": 0,

"upper": 75,

"value": 0

},

{

"component": "parametric-plate-buckling",

"name": "T1",

"lower": 0,

"upper": 75,

"value": 0

}

],

"output_variables": [

{

"component": "parametric-plate-buckling",

"type": "objective",

"name": "mass",

"value": 0

},

{

"component": "parametric-plate-buckling",

"type": "constraint",

"name": "buckling_factors",

"value": [

0

],

"lower": 75.0

}

],

"driver": {

"type": "optimisation"

},

"visualise": [

"n2_diagram",

"plot_history"

]

}

}

],

"connections": [],

"workflow": {

"start": "parametric-plate-buckling",

"end": "parametric-plate-buckling",

"driver": "open-mdao"

}

}

The question marks next to the component names indicate that they are missing some data.

To fully define them, we need to upload all the components’ setup.py, compute.py, requirements.txt and user input files, as described in the next sections.

7.2.2. Update the plate component#

The parametric plate component performs 3 main tasks:

It creates a set of analysis input files from the component parameters and design variable inputs;

It executes a CalculiX CrunchiX finite element analysis;

It then reads the analysis outputs and returns the model mass and buckling load factors as component outputs.

To achieve the first task, we first use CalculiX GraphiX to create the plate 2D geometry and mesh this using second order S8 elements. This 2D mesh is then used to extrude solid elements for each composite ply. The extrusion thickness at each node is calculated from the local RTS shearing angle, which is linearly interpolated from the two closest control point values (determined by projecting the node onto the line of control points).

Note that this analysis workflow could be generalised by splitting it up into 3 components, one for each task.

To update the parametric plate component:

Select the component in the workspace to edit it.

Copy the contents of the

setup.py,compute.py,requirements.txtfiles from below into a text editor, save them locally. Then upload them under thePropertiestab.Copy the contents of the

ccx_compression_buckle.inpfile from below into a text editor and save it locally. Then upload it under theParameterstab by selectingupload user input files. The other parameters, inputs and outputs should have been pre-populated by loading the session file in the previous section.Select

Save datato save and close the component.

from datetime import datetime

from pathlib import Path

def setup(

inputs: dict = {"design": {}, "implicit": {}, "setup": {}},

outputs: dict = {"design": {}, "implicit": {}, "setup": {}},

parameters: dict = {

"user_input_files": [],

"inputs_folder_path": "",

"outputs_folder_path": "",

},

) -> dict:

"""Editable setup function."""

message = f"{datetime.now().strftime('%Y%m%d-%H%M%S')}: Setup completed."

return {"message": message}

""" Create a 3D element mesh for the RTS panel buckling analysis. """

from shutil import copy2

from datetime import datetime

from pathlib import Path

from math import sqrt, floor, ceil, cos, sin, radians, log10

import numpy as np

import itertools

import time

from functools import wraps

from contextlib import redirect_stdout

from calculix import execute_cgx, execute_fea

PARAMS = {

"length_x": 1.250,

"width_y": 0.75,

"split_at_x": [0.25, 1.0],

"split_at_y": [0.25, 0.5],

"boundary_conditions": {

"fixed_y0": {"lines": [0, 1, 2], "SPC": "23"},

"fixed_x0": {"lines": [9, 10, 11], "SPC": "13"},

"support_z": {

"lines": range(12, 24),

"SPC": "3",

},

"support_ymax": {

"lines": [6, 7, 8],

"kinematic": "23",

"ref_node_SPC": "346",

"surface_vector": [0.0, 1.0, 0.0],

},

"loaded_xmax": {

"lines": [3, 4, 5],

"kinematic": "13",

"ref_node_SPC": "356",

"surface_vector": [1.0, 0.0, 0.0],

"ref_node_forces": [-10000.0, 0.0, 0.0],

},

},

"edge_length": 0.025,

"material": {

"E1": 163.0e9,

"E2": 12.0e9,

"nu12": 0.3,

"G12": 5.0e9,

"thickness": 0.000125,

"density": 1571.0,

"tape_width": 0.100,

"stress_allowables": {},

"name": "IM7_8552",

"description": " Units are: kg, m; data from Groh_2015.",

},

"plies": [

{

"combine_plus_minus_plies": True,

"control_pts": [

{"d": -0.01, "id": "T1", "inc_angle": 69},

{"d": 0, "id": "T1", "inc_angle": 69},

{"d": 0.125, "id": "T0", "inc_angle": 0},

{"d": 0.25, "id": "T1", "inc_angle": 69},

{"d": 0.375, "id": "T0", "inc_angle": 0},

{"d": 0.5, "id": "T1", "inc_angle": 69},

{"d": 0.625, "id": "T0", "inc_angle": 0},

{"d": 0.75, "id": "T1", "inc_angle": 69},

{"d": 0.76, "id": "T1", "inc_angle": 69},

],

"path_end": [0, 0.75, 0],

"path_start": [0, 0, 0],

"ply_ref_angle": 90,

"ply_ref_thickness_multiplier": 10,

},

{

"combine_plus_minus_plies": True,

"control_pts": [{"d": -0.01, "inc_angle": 0}, {"d": 0.76, "inc_angle": 0}],

"path_end": [0, 0.75, 0],

"path_start": [0, 0, 0],

"ply_ref_angle": 90,

"ply_ref_thickness_multiplier": 8,

},

{

"combine_plus_minus_plies": True,

"control_pts": [

{"d": -0.01, "id": "T1", "inc_angle": 69},

{"d": 0, "id": "T1", "inc_angle": 69},

{"d": 0.125, "id": "T0", "inc_angle": 0},

{"d": 0.25, "id": "T1", "inc_angle": 69},

{"d": 0.375, "id": "T0", "inc_angle": 0},

{"d": 0.5, "id": "T1", "inc_angle": 69},

{"d": 0.625, "id": "T0", "inc_angle": 0},

{"d": 0.75, "id": "T1", "inc_angle": 69},

{"d": 0.76, "id": "T1", "inc_angle": 69},

],

"path_end": [0, 0.75, 0],

"path_start": [0, 0, 0],

"ply_ref_angle": 90,

"ply_ref_thickness_multiplier": 10,

},

],

"mesh_files": {

"mesh": "all.msh",

"solid_mesh": "solid_mesh.inp",

"materials": "materials.inp",

"element_sets": "element_sets.inp",

"solid_sections": "solid_sections.inp",

"node_sets": "node_sets.inp",

"surfaces": "surfaces.inp",

"constraints": "constraints.inp",

"loads": "loads.inp",

},

"analysis_file": "ccx_compression_buckle.inp",

"number_of_modes": 10,

"user_input_files": [],

"inputs_folder_path": Path(__file__).parent,

"outputs_folder_path": Path(__file__).parent / "outputs",

}

def timeit(func):

@wraps(func)

def wrapper_timer(*args, **kwargs):

tic = time.perf_counter()

value = func(*args, **kwargs)

toc = time.perf_counter()

elapsed_time = toc - tic

print(

f"Elapsed time for function '{func.__name__}': {elapsed_time:0.4f} seconds"

)

return value

return wrapper_timer

def compute(

inputs: dict = {"design": {}, "implicit": {}, "setup": {}},

outputs: dict = {"design": {}, "implicit": {}, "setup": {}},

partials: dict = {},

options: dict = {},

parameters: dict = {

"user_input_files": [],

"inputs_folder_path": "",

"outputs_folder_path": "",

},

) -> dict:

"""Editable compute function."""

run_folder = Path(parameters["outputs_folder_path"])

with open(run_folder / "run.log", "w", encoding="utf-8") as f:

with redirect_stdout(f):

resp = main(

inputs=inputs,

outputs=outputs,

partials=partials,

options=options,

parameters=parameters,

)

return resp

def main(

inputs: dict = {"design": {}, "implicit": {}, "setup": {}},

outputs: dict = {"design": {}, "implicit": {}, "setup": {}},

partials: dict = {},

options: dict = {},

parameters: dict = {

"user_input_files": [],

"inputs_folder_path": "",

"outputs_folder_path": "",

},

):

inputs_folder = Path(parameters["inputs_folder_path"])

if not (inputs_folder / parameters["analysis_file"]).is_file():

raise FileNotFoundError(

f"{parameters['analysis_file']} needs to be uploaded by the user."

)

print("Starting user function evaluation.")

run_folder = Path(parameters["outputs_folder_path"])

# set design variables

if inputs["design"]:

update_parameters_with_inputs(parameters, inputs)

print("Applied design inputs.")

# 1) Define a 2D mould surfaces in CGX and generate the 2D mesh

cgx_input_file = get_geometry(

length_x=parameters["length_x"],

width_y=parameters["width_y"],

split_at_x=parameters["split_at_x"],

split_at_y=parameters["split_at_y"],

boundary_conditions=parameters["boundary_conditions"],

edge_length=parameters["edge_length"],

run_folder=run_folder,

)

resp = execute_cgx(infile=cgx_input_file.name, run_folder=run_folder)

with open(run_folder / "cgx.log", "w", encoding="utf-8") as f:

f.write(resp["stdout"])

if not resp["returncode"] == 0:

raise ChildProcessError(

f'cgx returned non-zero exit status {resp["returncode"]}'

)

# read the 2D mesh from CGX output file

elements, nodes, constraints = get_2Dmesh(

mesh_files=parameters["mesh_files"],

run_folder=run_folder,

bcs=parameters["boundary_conditions"],

)

# 2) Calculate the element normals, and then the node normal

corner_nodes = set()

set_element_normals(elements=elements, nodes=nodes, corner_nodes=corner_nodes)

set_node_normals(nodes=nodes, elements=elements)

# 3) Offset the 2D mesh nodes by local thickness distribution for each laminate substack

nid_offset = 10 ** ceil(log10(max(nodes.keys())))

eid_offset = 10 ** ceil(log10(max(elements.keys())))

materials = {}

element_sets = {}

set_name_format = "P{:d}_A{:.3f}"

for plyid, ply in enumerate(parameters["plies"]):

# define functions to interpolate rts ply local properties

f_inc_angle, f_thickness, upath = get_rts_distributions(

ply, ref_thickness=parameters["material"]["thickness"]

)

offset_nodes(

plyid,

nodes,

constraints,

f_inc_angle,

f_thickness,

upath,

set_of_corner_nodes=corner_nodes,

start=np.array(ply["path_start"]),

nid_offset=nid_offset,

)

# 4) create 3D elements from 2D mesh and offset nodes

offset_elements(

plyid,

elements,

element_sets,

constraints,

f_inc_angle,

f_thickness,

upath,

start=np.array(ply["path_start"]),

eid_offset=eid_offset,

nid_offset=nid_offset,

nodes=nodes,

)

# 5) calculate the local material properties for each group of elements from the reference angle and shearing angles

set_materials(

plyid,

materials,

list(element_sets[plyid].keys()),

ply,

parameters["material"],

nformat=set_name_format,

)

# calculate reference node positions for the kinematic constraints

update_kinematic_constraints_ref_nodes(

constraints, nodes, offset=nid_offset * (len(parameters["plies"]) * 2 + 1)

)

# calculate the plate mass from elements

volume = get_volume(elements)

mass = volume * parameters["material"]["density"]

# 6) output the mesh to file

fname = parameters["mesh_files"]

write_solid_mesh(nodes, elements, run_folder=run_folder, file=fname["solid_mesh"])

write_materials(materials, run_folder=run_folder, file=fname["materials"])

write_element_sets(

element_sets, set_name_format, run_folder=run_folder, file=fname["element_sets"]

)

write_solid_sections(

materials, set_name_format, run_folder=run_folder, file=fname["solid_sections"]

)

write_node_sets(constraints, run_folder=run_folder, file=fname["node_sets"])

write_surface(constraints, run_folder=run_folder, file=fname["surfaces"])

write_constraints(constraints, run_folder=run_folder, file=fname["constraints"])

write_loading(constraints, run_folder=run_folder, file=fname["loads"])

print("Created CCX solid mesh files.")

# 7) Perform ccx FEM analysis

infile = copy2(

inputs_folder / parameters["analysis_file"],

run_folder / parameters["analysis_file"],

)

resp = execute_fea(infile.stem, run_folder=run_folder)

with open(run_folder / "ccx.log", "w", encoding="utf-8") as f:

f.write(resp["stdout"])

if not resp["returncode"] == 0:

raise ChildProcessError(

f'ccx returned non-zero exit status {resp["returncode"]}'

)

# check output has been saved

outfile = run_folder / (infile.stem + ".dat")

if not outfile.is_file():

raise FileNotFoundError(f"{str(outfile)} is not a file.")

print("Executed CCX FEM analysis.")

buckling_factors = get_buckling_factors(

outfile, number_modes=parameters["number_of_modes"]

)

outputs["design"]["mass"] = mass

outputs["design"]["buckling_factors"] = buckling_factors[0]

message = f"{datetime.now().strftime('%Y%m%d-%H%M%S')}: Executed Calculix finite element analysis."

print(message)

return {"message": message, "outputs": outputs}

@timeit

def update_parameters_with_inputs(parameters, inputs):

input_data = inputs["design"] # ["ply-ctrl_pt_id-inc_angle": value, ]

for key, value in input_data.items():

if not key in ["T0", "T1"]:

raise ValueError('Input key should be one of "T0", "T1"')

for ply in parameters["plies"]:

for pt in ply["control_pts"]:

if "id" in pt and pt["id"] == key:

pt["inc_angle"] = value

return None

@timeit

def get_geometry(

length_x,

width_y,

split_at_x,

split_at_y,

boundary_conditions,

edge_length,

fname="cgx_2d_mesh.fdb",

run_folder=None,

):

# corner points 1-4

points = [[0.0, 0.0], [length_x, 0.0], [length_x, width_y], [0.0, width_y]]

# side points

points.extend(

[

[split_at_x[0], 0.0],

[split_at_x[1], 0.0],

[length_x, split_at_y[0]],

[length_x, split_at_y[1]],

[split_at_x[1], width_y],

[split_at_x[0], width_y],

[0.0, split_at_y[1]],

[0.0, split_at_y[0]],

]

)

# mid-panel nodes

points.extend(

[

[split_at_x[0], split_at_y[0]],

[split_at_x[1], split_at_y[0]],

[split_at_x[1], split_at_y[1]],

[split_at_x[0], split_at_y[1]],

]

)

# all at z = 0

[p.append(0.0) for p in points]

# Lines 0 to 11 are the outside bounds defined by point indices

lines = [

[0, 4], # 0

[4, 5],

[5, 1],

[1, 6],

[6, 7], # 4

[7, 2],

[2, 8],

[8, 9],

[9, 3], # 8

[3, 10],

[10, 11],

[11, 0],

]

# split lines 12 to 23 defined by point indices

lines.extend(

[

[4, 12], # 12

[5, 13],

[6, 13],

[7, 14],

[8, 14], # 16

[9, 15],

[10, 15],

[11, 12],

[12, 13], # 20

[13, 14],

[14, 15],

[15, 12],

]

)

# add number of elements per edge

def nele(pt1, pt2, edge):

p1 = points[pt1]

p2 = points[pt2]

l = sqrt((p2[0] - p1[0]) ** 2 + (p2[1] - p1[1]) ** 2 + (p2[2] - p1[2]) ** 2)

return floor(l / edge)

[line.append(nele(line[0], line[1], edge_length)) for line in lines]

# surfaces defined by line indices (negative for direction reversal)

surfaces = [

[0, 12, -19, 11],

[1, 13, -20, -12],

[2, 3, 14, -13],

[4, 15, -21, -14],

[5, 6, 16, -15],

[7, 17, -22, -16],

[8, 9, 18, -17],

[10, 19, -23, -18],

[20, 21, 22, 23],

]

commands = get_commands(points, lines, surfaces, boundary_conditions)

# write string of commands to file

with open(run_folder / fname, "w", encoding="utf-8") as f:

f.write("".join(commands))

cgx_input_file = run_folder / fname

return cgx_input_file

def divide_chunks(l, n):

if not isinstance(l, list):

l = list(l)

# looping till length l

for i in range(0, len(l), n):

yield l[i : i + n]

@timeit

def get_commands(

points,

lines,

surfaces,

boundary_conditions,

max_entries_per_line=9,

cgx_ele_type=10, # s8 elements

nele_multiplier=2, # for s8 elements

merge_tol=0.001,

solver="abq",

):

"""create string of all cgx input commands"""

commands = []

# points

for entity_id, point in enumerate(points):

commands.append(

f"PNT P{entity_id:05d} {point[0]:e} {point[1]:e} {point[2]:e}\n"

)

commands.append("# =============== \n")

# lines

for entity_id, line in enumerate(lines):

if len(line) == 3: # straight line

commands.append(

f"LINE L{entity_id:05d} P{line[0]:05d} P{line[1]:05d} {line[2]*nele_multiplier:d} \n"

)

commands.append("# =============== \n")

# surfaces

for entity_id, surf in enumerate(surfaces):

commands.append(

f"GSUR V{entity_id:05d} + BLEND "

+ " ".join(

[f"+ L{line:05d}" if line >= 0 else f"- L{-line:05d}" for line in surf]

)

+ "\n"

)

commands.append("# =============== \n")

# SPC and load sets

for name, bc in boundary_conditions.items():

for chunk in divide_chunks(bc["lines"], max_entries_per_line):

commands.append(

f"SETA {name.upper()} l "

+ " ".join([f"L{int(line):05d}" for line in chunk])

+ "\n"

)

commands.append("# =============== \n")

# surface meshes

for entity_id, _ in enumerate(surfaces):

commands.append(f"MSHP V{entity_id:05d} s {cgx_ele_type:d} 0 1.000000e+00\n")

commands.append("# =============== \n")

# custom export statement

commands.append("mesh all\n")

commands.append(f"merg n all {merge_tol:6f} 'nolock'\n")

commands.append("comp nodes d\n")

for name, bc in boundary_conditions.items():

commands.append(f"comp {name.upper()} d\n")

# commands.append(f"send {name.upper()} {solver} spc {bc['SPC']}\n")

commands.append(f"send {name.upper()} {solver} names\n")

commands.append("# =============== \n")

commands.append(f"send all {solver} \n")

commands.append("quit\n")

return commands

@timeit

def get_2Dmesh(mesh_files, run_folder, bcs):

elements, nodes = get_nodes_and_elements(run_folder, file=mesh_files["mesh"])

constraints = get_constraints(run_folder, bcs=bcs)

return elements, nodes, constraints

def get_nodes_and_elements(run_folder, file):

with open(run_folder / file, "r", encoding="utf-8") as f:

lines = f.readlines()

read_nodes = False

read_elements = False

ele_type = None

nodes = {}

elements = {}

for line in lines:

if line.startswith("*NODE"): # all nodes in one set assumed

print("start reading nodes.")

read_nodes = True

read_elements = False

ele_type = None

continue

elif line.startswith("*ELEMENT"): # all elements in one set assumed

print("start reading elements.")

read_nodes = False

read_elements = True

ele_type = {

data.split("=")[0].strip(): data.split("=")[1].strip()

for data in line.split(",")

if "=" in data

}["TYPE"]

continue

elif read_nodes:

data = line.split(",")

# parse nodes into { ID: {"global_xyz": [x,y,z]}}

nodes[int(data[0])] = {"global_xyz": [float(v) for v in data[1:]]}

elif read_elements:

data = line.split(",")

# parse elements into { ID: {"type": S8, "nodes": [1-8]}}

elements[int(data[0])] = {

"type": ele_type,

"nodes": [int(v) for v in data[1:]],

}

return elements, nodes

def get_constraints(run_folder, bcs):

all_constrained_nodes = set()

def get_constraint_starting_nodes(constraints):

for cname, constraint in constraints.items():

with open(

run_folder / (cname.upper() + ".nam"), "r", encoding="utf-8"

) as f:

lines = f.readlines()

read_nodes = False

for line in lines:

if line.startswith("*NSET"):

print(f"start reading node set {cname}.")

read_nodes = True

continue

elif read_nodes:

data = line.split(",")

if int(data[0]) not in all_constrained_nodes:

constraint["nodes"].add(int(data[0]))

all_constrained_nodes.add(int(data[0]))

else:

print(

f"Node {int(data[0])} is removed from constraint {cname.upper()} as it is already constrained."

)

constraints = {"SPCs": {}, "kinematic_MPCs": {}}

for cname, constraint in bcs.items():

if "SPC" in constraint:

ctype = "SPCs"

constraints[ctype][cname] = {"nodes": set(), **constraint}

elif "kinematic" in constraint:

ctype = "kinematic_MPCs"

constraints[ctype][cname] = {"nodes": set(), "faces": set(), **constraint}

# get constraints in order to avoid over-constraining nodes where constraints overlap

get_constraint_starting_nodes(

constraints["kinematic_MPCs"]

) # define face constraints first

get_constraint_starting_nodes(

constraints["SPCs"]

) # exclude nodes in face constraints

return constraints

@timeit

def set_element_normals(elements, nodes, corner_nodes):

for _, element in elements.items():

centroid = [0.0, 0.0, 0.0]

for nid in element["nodes"]:

xyz = nodes[nid]["global_xyz"]

centroid = [c1 + c2 for c1, c2 in zip(centroid, xyz)]

centroid = [c / len(element["nodes"]) for c in centroid]

element["global_xyz"] = centroid

## TODO for each element normal is the average of the normals calculated at the elemnent nodes from the element edges ( sum of vectors / nb nodes)

# (assume n = [0,0,1] for the flat panel)

element["normal"] = [0.0, 0.0, 1.0]

if element["type"] == "S8":

corner_nodes.update(element["nodes"][:4])

return None

@timeit

def set_node_normals(nodes, elements):

for nid in nodes:

## TODO for each node, find the connected elements and average normal at the node as sum of vectors / nb connected elements

# (assume n = [0,0,1] for the flat panel)

nodes[nid]["normal"] = [0.0, 0.0, 1.0]

return None

def piecewise_linear_angle_interp(x, ranges, ctrl_points):

f_angles = lambda x, a0, a1, d0, d1: (a1 - a0) / (d1 - d0) * (x - d0) + a0

for d, a in zip(ranges, ctrl_points):

if x >= d[0] and x < d[1]:

return f_angles(x, a[0], a[1], d[0], d[1])

raise ValueError(f"x value {x} is outside control point range.")

@timeit

def get_rts_distributions(ply, ref_thickness):

# get path unit vector

upath = np.array(ply["path_end"]) - np.array(ply["path_start"])

upath = upath / np.linalg.norm(upath)

# linear interpolation

ranges = []

ctrl_points = []

for p0, p1 in zip(ply["control_pts"][:-1], ply["control_pts"][1:]):

ranges.append((p0["d"], p1["d"]))

ctrl_points.append((p0["inc_angle"], p1["inc_angle"]))

# input to f_inc_angle is dot product of upath with vector from path start to node

f_inc_angle = {

"f": piecewise_linear_angle_interp,

"args": [ranges, ctrl_points],

}

f_thickness = (

lambda x: ply["ply_ref_thickness_multiplier"] * ref_thickness / cos(radians(x))

)

return f_inc_angle, f_thickness, upath

def project_to_point(xyz, start, upath, f_inc_angle, f_thickness):

vector2node = np.array(xyz) - start

projected_length = np.dot(upath, vector2node)

inc_angle = f_inc_angle["f"](projected_length, *f_inc_angle["args"])

thickness = f_thickness(inc_angle)

return {"inc_angle": inc_angle, "thickness": thickness}

def offset_point_by_vector(magnitude, vector, pt):

return [c + v * magnitude for v, c in zip(vector, pt)]

@timeit

def offset_nodes(

plyid,

nodes,

constraints,

f_inc_angle,

f_thickness,

upath,

set_of_corner_nodes,

start,

nid_offset,

):

## project the shearing angle and thickness values to the model nodes and centroids in a direction normal to upath

for nid, node in list(nodes.items()):

# filter nodes by ID - take only nodes at the bottom of the current layer

if nid > plyid * 2 * nid_offset and nid < (plyid * 2 + 1) * nid_offset:

props = project_to_point(

node["global_xyz"],

start,

upath,

f_inc_angle,

f_thickness,

)

thickness = props["thickness"]

# save offset nodes

new_nids = []

if nid - plyid * 2 * nid_offset in set_of_corner_nodes:

nodes[nid + nid_offset] = {

"normal": node["normal"],

"global_xyz": offset_point_by_vector(

thickness / 2, node["normal"], node["global_xyz"]

),

} # mid-height node

new_nids.append(nid + nid_offset)

nodes[nid + nid_offset * 2] = {

"normal": node["normal"],

"global_xyz": offset_point_by_vector(

thickness, node["normal"], node["global_xyz"]

),

} # top node

new_nids.append(nid + nid_offset * 2)

# update the spc constraint node sets

for cname, constraint in constraints["SPCs"].items():

if nid in constraint["nodes"]:

constraint["nodes"].update(new_nids)

return None

@timeit

def offset_elements(

plyid,

elements,

element_sets,

constraints,

f_inc_angle,

f_thickness,

upath,

start,

eid_offset,

nid_offset,

nodes,

):

# element faces from ccx manual for C3D20/ C3D20R elements

faces = {

"S1": [n - 1 for n in (1, 2, 3, 4)],

"S2": [n - 1 for n in (5, 8, 7, 6)],

"S3": [n - 1 for n in (1, 5, 6, 2)],

"S4": [n - 1 for n in (2, 6, 7, 3)],

"S5": [n - 1 for n in (3, 7, 8, 4)],

"S6": [n - 1 for n in (4, 8, 5, 1)],

}

## TODO check that the offset values at each node are small compared to the edge

# lengths of the connected elements (<1/5 edge?) to avoid badly shaped elements

## project the shearing angle and thickness values to the model nodes and centroids in a direction normal to upath

element_sets[plyid] = {}

for eid, element in list(elements.items()):

# filter 2D elements - reference for the property calculation

if element["type"] == "S8":

props = project_to_point(

element["global_xyz"],

start,

upath,

f_inc_angle,

f_thickness,

)

inc_angle = props["inc_angle"]

thickness = props["thickness"]

# save offset element

new_eid = eid + eid_offset * (plyid + 1)

nids = [

*[

n + nid_offset * 2 * plyid for n in element["nodes"][:4]

], # base corners

*[

n + nid_offset * 2 * (1 + plyid) for n in element["nodes"][:4]

], # top corners

*[

n + nid_offset * 2 * plyid for n in element["nodes"][4:]

], # base mid-side

*[

n + nid_offset * 2 * (1 + plyid) for n in element["nodes"][4:]

], # top mid-side

*[

n + nid_offset * (1 + 2 * plyid) for n in element["nodes"][:4]

], # mid-height nodes

]

volume = hexahedron_volume_from_nodes(nids[:8], nodes)

elements[new_eid] = {

"global_xyz": offset_point_by_vector(

thickness * (plyid + 1 / 2),

element["normal"],

element["global_xyz"],

),

"type": "C3D20R",

"inc_angle": inc_angle,

"t": thickness,

"nodes": nids,

"volume": volume,

}

# Create sets of elements by ply and common inc_angle.

if inc_angle in element_sets[plyid]:

element_sets[plyid][inc_angle].append(new_eid)

else:

element_sets[plyid][inc_angle] = [new_eid]

# update kinematic constraints if needed

update_kinematic_constraints(constraints, nids, faces, new_eid, nodes)

return None

def hexahedron_volume_from_nodes(nids, nodes):

n = lambda i: np.array(nodes[nids[i - 1]]["global_xyz"])

# sum the volume of the 5 tetrahedrons composing the hex

volume = 0.0

for tet in (

(n(1), n(2), n(4), n(5)),

(n(3), n(2), n(4), n(7)),

(n(5), n(6), n(7), n(2)),

(n(5), n(7), n(8), n(4)),

(n(2), n(4), n(7), n(5)),

):

volume += get_tetrahedron_volume(tet)

return volume

def get_tetrahedron_volume(tet):

if not all([isinstance(n, np.ndarray) for n in tet]) or not len(tet) == 4:

raise ValueError(

"input should be list of 4 np.array(xyz) coordinates of tet corners."

)

matrix = np.array(

[

tet[0] - tet[3],

tet[1] - tet[3],

tet[2] - tet[3],

]

)

return 1 / 6 * np.abs(np.linalg.det(matrix))

def update_kinematic_constraints(constraints, nids, faces, new_eid, nodes):

# update the kinematic constraint node sets and face=(element,faceID) sets

# NOTE:

# the function is exited after the first constraint on an element is found,

# this avoids over-constraining element nodes, which results in error messages

iterables = [constraints["kinematic_MPCs"].values(), faces.items()]

for constraint, (face, face_node_indices) in list(itertools.product(*iterables)):

face_nids = [nids[i] for i in face_node_indices]

if any([n in constraint["nodes"] for n in face_nids]):

face_nodes = [nodes[i] for i in face_nids]

face_vector = get_surface_normal_from_nodes(face_nodes)

if np.dot(

face_vector, np.array(constraint["surface_vector"])

) > 0.9 * np.linalg.norm(face_vector):

# update the face set

constraint["faces"].add((new_eid, face))

# update the node set

constraint["nodes"].update(face_nids)

return

def get_volume(elements):

volume = 0.0

for e in elements.values():

if e["type"] == "C3D20R":

volume += e["volume"]

return volume

@timeit

def update_kinematic_constraints_ref_nodes(constraints, nodes, offset):

nid = offset + 1

for constraint in constraints["kinematic_MPCs"].values():

face_nodes = [nodes[i] for i in constraint["nodes"]]

constraint["ref_node"] = {nid: {"global_xyz": get_mid_point(face_nodes)}}

nid += 1

def get_surface_normal_from_nodes(nodes: list) -> np.ndarray:

# assumes coplanar nodes on face by only using first 3 nodes

if not len(nodes) >= 3:

raise ValueError("Need at least 3 nodes to calculate surface normal vector.")

v01 = np.array(nodes[1]["global_xyz"]) - np.array(nodes[0]["global_xyz"])

v02 = np.array(nodes[2]["global_xyz"]) - np.array(nodes[0]["global_xyz"])

# TODO check angle between vectors is > 10 deg for more general meshes

return np.cross(v02, v01) # order so that the norm points out of the element

def get_mid_point(face_nodes):

# find the average xyz position from a set of nodes

mid_point = np.zeros(3)

for node in face_nodes:

mid_point += np.array(node["global_xyz"])

mid_point /= len(face_nodes)

return list(mid_point)

@timeit

def set_materials(plyid, materials, set_inc_angles, ply, ref_material, nformat):

# get composite ply Q matrix

q_matrix = get_Qmatrix(ref_material)

# calculate D from A/t, from the Q matrix and from the fibre angles

set_D_matrix(plyid, materials, q_matrix, ply, set_inc_angles, ref_material, nformat)

return None

def get_Qmatrix(material):

modulus_E1 = material["E1"]

modulus_E2 = material["E2"]

pr_nu12 = material["nu12"]

modulus_G12 = material["G12"]

pr_nu21 = pr_nu12 * modulus_E2 / modulus_E1

denominator = 1 - pr_nu12 * pr_nu21

q11 = modulus_E1 / denominator

q22 = modulus_E2 / denominator

q12 = pr_nu12 * modulus_E2 / denominator

q66 = modulus_G12

return np.array([[q11, q12, 0.0], [q12, q22, 0.0], [0.0, 0.0, q66]])

def rotate_q_matrix(angle, q):

s = lambda angle: sin(radians(angle))

c = lambda angle: cos(radians(angle))

T_mat = np.array(

[

[c(angle) ** 2, s(angle) ** 2, 2 * c(angle) * s(angle)],

[s(angle) ** 2, c(angle) ** 2, -2 * c(angle) * s(angle)],

[-c(angle) * s(angle), c(angle) * s(angle), c(angle) ** 2 - s(angle) ** 2],

]

)

R_mat = np.array(

[[1.0, 0.0, 0.0], [0.0, 1.0, 0.0], [0.0, 0.0, 2.0]]

) # Reuter matrix

# equation 2.82 from Mechanics of Composite materials

q_rotated = np.linalg.inv(T_mat) @ q @ R_mat @ T_mat @ np.linalg.inv(R_mat)

return q_rotated

def set_D_matrix(

plyid, materials, q_matrix, ply, set_inc_angles, ref_material, nformat

):

def is_pos_def(A):

if np.allclose(A, A.T, atol=1e-3):

try:

np.linalg.cholesky(A)

return True

except np.linalg.LinAlgError:

return False

else:

return False

# indices for upper triangular 6x6 matrix in column by column order

# (order for calculix anisotropic material elasticity inputs)

indices = [[], []]

rows_upper_triangular = 1

for col in range(6):

for row in range(rows_upper_triangular):

indices[0].append(row)

indices[1].append(col)

rows_upper_triangular += 1

materials[plyid] = {}

for inc_angle in set_inc_angles:

if ply["combine_plus_minus_plies"]:

rotations = [-inc_angle, inc_angle]

else:

rotations = [inc_angle]

# calculate A/t matrix

a_matrix_by_t = np.zeros([3, 3])

for r in rotations:

a_matrix_by_t += rotate_q_matrix(angle=r + ply["ply_ref_angle"], q=q_matrix)

a_matrix_by_t = a_matrix_by_t / len(rotations)

# derive the dimensionless D stiffness matrix in 3D, check that it is positive definite

d_matrix = np.zeros([6, 6])

d_matrix[:2, :2] = a_matrix_by_t[:2, :2]

d_matrix[:2, 3] = a_matrix_by_t[:2, 2]

d_matrix[3, :2] = a_matrix_by_t[2, :2]

d_matrix[3, 3] = a_matrix_by_t[2, 2]

d_matrix[2, 2] = ref_material["E2"]

d_matrix[4, 4] = ref_material["G12"]

d_matrix[5, 5] = ref_material["G12"]

if not is_pos_def(d_matrix):

raise ValueError("Calculated stiffness matrix is not positive definite.")

materials[plyid][inc_angle] = {

"name": nformat.format(plyid, inc_angle),

"D_matrix": d_matrix[tuple(indices)].tolist(),

"density": ref_material["density"],

}

return None

@timeit

def write_solid_mesh(nodes, elements, run_folder=None, file="solid_mesh.inp"):

lines = []

# nodes

lines.append("*NODE, NSET=Nall\n")

for nid, node in nodes.items():

lines.append("{:6d},{:e},{:e},{:e}\n".format(nid, *node["global_xyz"]))

# elements

lines.append("*ELEMENT, TYPE=C3D20R, ELSET=Eall\n")

format_C3D20R = "".join(["{:6d},"] * 16 + ["\n"] + ["{:6d},"] * 5)[:-1] + "\n"

for eid, element in elements.items():

if element["type"] == "C3D20R":

lines.append(format_C3D20R.format(eid, *element["nodes"]))

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

return None

@timeit

def write_materials(materials, run_folder=None, file="materials.inp"):

lines = []

format_aniso = (

"".join(["{:e},"] * 8 + ["\n"] + ["{:e},"] * 8 + ["\n"] + ["{:e},"] * 5)[:-1]

+ "\n"

)

for ply in materials.values():

for material in ply.values():

lines.append(f"*MATERIAL,NAME={material['name']}\n")

lines.append(

"*ELASTIC, TYPE =ANISO\n" + format_aniso.format(*material["D_matrix"])

)

lines.append("*DENSITY\n{:e}\n".format(float(material["density"])))

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

@timeit

def write_element_sets(

element_sets, set_name_format, run_folder=None, file="element_sets.inp"

):

lines = []

for plyid, plyset in element_sets.items():

for inc_angle, elset in plyset.items():

lines.append(

"*ELSET,ELSET=E" + set_name_format.format(plyid, inc_angle) + "\n"

)

for chunk in divide_chunks(elset, 16):

# note trailing comas are no a problem for ccx or abaqus

lines.append(", ".join([f"{int(eid):d}" for eid in chunk]) + ",\n")

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

@timeit

def write_solid_sections(

materials, set_name_format, run_folder=None, file="solid_sections.inp"

):

lines = []

for plyid, ply in materials.items():

for inc_angle in ply.keys():

name = set_name_format.format(plyid, inc_angle)

lines.append("*SOLID SECTION,MATERIAL=" + name)

lines.append(",ELSET=E" + name + "\n")

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

@timeit

def write_node_sets(constraints, run_folder=None, file="node_sets.inp"):

lines = []

for cname, constraint in constraints["SPCs"].items():

lines.append("*NSET,NSET=N" + cname.upper() + "\n")

for chunk in divide_chunks(constraint["nodes"], 16):

# note trailing comas are no a problem for ccx or abaqus

lines.append(", ".join([f"{int(eid):d}" for eid in chunk]) + ",\n")

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

def write_surface(constraints, run_folder=None, file="surfaces.inp"):

lines = []

for cname, constraint in constraints["kinematic_MPCs"].items():

lines.append("*SURFACE, NAME=S" + cname.upper() + "\n")

for face in constraint["faces"]:

lines.append(f"{face[0]:6d},{face[1]}\n")

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

def write_constraints(constraints, run_folder=None, file="constraints.inp"):

lines = []

# spc constraints

lines.append("*BOUNDARY\n")

for cname, constraint in constraints["SPCs"].items():

for dof in constraint["SPC"]:

lines.append(f"N{cname.upper()}, {dof}, ,\n") # NSET, DOF

# kinematic constraints

for cname, constraint in constraints["kinematic_MPCs"].items():

nid = list(constraint["ref_node"].keys())[0]

lines.append(f"*NODE, NSET=N{cname.upper()}\n")

lines.append(

"{:6d},{:e},{:e},{:e}\n".format(

nid, *constraint["ref_node"][nid]["global_xyz"]

)

)

lines.append(

f"*COUPLING, REF NODE={nid}, SURFACE=S{cname.upper()}, CONSTRAINT NAME={cname.upper()}\n"

)

lines.append("*KINEMATIC\n")

for dof in constraint["kinematic"]:

lines.append(f"{dof}\n") # DOF

lines.append("*BOUNDARY\n")

for dof in constraint["ref_node_SPC"]:

lines.append(f"{nid:6d}, {dof}, ,\n")

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

def write_loading(constraints, run_folder=None, file="loads.inp"):

lines = []

for constraint in constraints["kinematic_MPCs"].values():

if "ref_node_forces" in constraint:

lines.append("*CLOAD\n")

nid = list(constraint["ref_node"].keys())[0]

for dof, value in enumerate(constraint["ref_node_forces"]):

if not value == 0.0:

lines.append(f"{nid:6d}, {dof+1:d}, {value:e}\n")

# write string of input lines to file

with open(run_folder / file, "w", encoding="utf-8") as f:

f.write("".join(lines))

def get_buckling_factors(outfile, number_modes):

with open(outfile, "r", encoding="utf-8") as f:

data = f.readlines()

index = 1

factors = []

for line in data[6 : int(7 + number_modes)]:

output = line.strip().split()

mode_no = int(output[0])

factor = float(output[1])

if not mode_no == index:

raise ValueError(

"Mode number doesn't match expected index. Check dat file."

)

index += 1

factors.append(factor)

return factors

if __name__ == "__main__":

design = {}

outputs = {

"mass": 0.0,

"buckling_factors": [0.0],

}

resp = main(

inputs={"design": design, "implicit": {}, "setup": {}},

outputs={"design": outputs, "implicit": {}, "setup": {}},

partials={},

options={},

parameters=PARAMS,

)

# assert np.isclose(resp["outputs"]["mass"], 8.836875, rtol=1e-6)

# assert np.isclose(resp["outputs"]["buckling_factors"][0], 1.126453, rtol=1e-6)

numpy==1.23.5

*HEADING

Model: Unsuported composite box normal modes

**********************

** NODES AND ELEMENTS

*INCLUDE,INPUT=solid_mesh.inp

**********************

** COMPOSITE PROPERTIES

*INCLUDE,INPUT=element_sets.inp

*INCLUDE,INPUT=materials.inp

*INCLUDE,INPUT=solid_sections.inp

**********************

** CONSTRAINTS

*INCLUDE,INPUT=node_sets.inp

*INCLUDE,INPUT=surfaces.inp

*INCLUDE,INPUT=constraints.inp

*STEP

*BUCKLE, SOLVER=SPOOLES

10

*INCLUDE,INPUT=loads.inp

*NODE OUTPUT

U

*ELEMENT OUTPUT

S

*END STEP

7.2.3. Update the driver component#

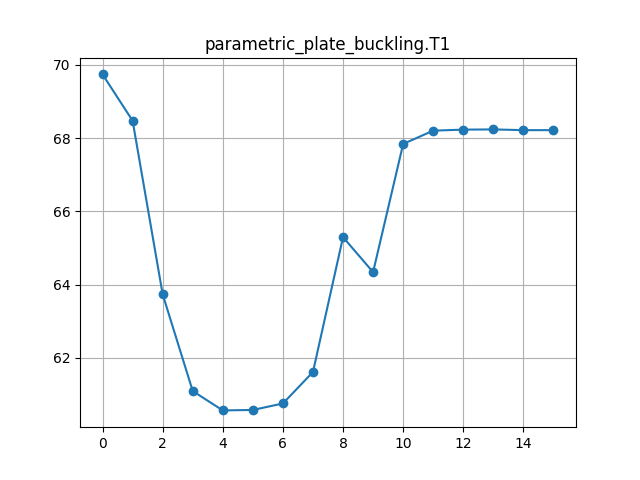

The driver component is identical to the OpenMDAO optimisation component used in the Simple optimisation problem example, except for the driver parameters, which have been adjusted for the plate optimisation problem:

The “input_variables” and “output_variables” parameters set the optimisation variables, objective and constraint functions.

The calculation of total derivatives across the chained components (using finite differencing) is requested by setting

"approx_totals": trueand"fd_step": 0.2in the driver parameters.Optimisation iteration history plots are requested by adding the “plot_history” option into the “visualise” parameter list.

To create the driver component:

Select the open-mdao component to edit it.

Copy the contents of the

setup.py,compute.py,requirements.txtfiles from below into a text editor, save them locally. Then upload them under thePropertiestab.Copy the contents of the

om_component.pyfile from below into a text editor and save it locally. Then upload it under theParameterstab by selectingupload user input files.Select

Save datato save and close the component.

from datetime import datetime

from pathlib import Path

def setup(

inputs: dict = {"design": {}, "implicit": {}, "setup": {}},

outputs: dict = {"design": {}, "implicit": {}, "setup": {}},

parameters: dict = {

"user_input_files": [],

"inputs_folder_path": "",

"outputs_folder_path": "",

},

) -> dict:

"""Editable setup function."""

if "driver" not in parameters:

# assume we want to run an optimisation with default settings

parameters["driver"] = {"type": "optimisation"}

message = f"{datetime.now().strftime('%Y%m%d-%H%M%S')}: Setup completed."

return {"message": message, "parameters": parameters}

from datetime import datetime

from pathlib import Path

import traceback

from contextlib import redirect_stdout

import numpy as np

import json

from copy import deepcopy

from concurrent.futures import ThreadPoolExecutor

import openmdao.api as om

from matplotlib import pyplot as plt # type: ignore

from om_component import OMexplicitComp, OMimplicitComp # type: ignore

OPENMDAO_REPORTS = None

OM_DEFAULTS = {

"nonlinear_solver": {

"class": om.NewtonSolver,

"kwargs": {"solve_subsystems": False},

},

"linear_solver": {

"class": om.DirectSolver,

"kwargs": {},

},

}

def compute(

inputs: dict = {"design": {}, "implicit": {}, "setup": {}},

outputs: dict = {"design": {}, "implicit": {}, "setup": {}},

partials: dict = {},

options: dict = {},

parameters: dict = {

"user_input_files": [],

"inputs_folder_path": "",

"outputs_folder_path": "",

},

) -> dict:

"""Editable compute function."""

print("OpenMDAO problem setup started.")

workflow = parameters["workflow"]

run_folder = Path(parameters["outputs_folder_path"])

all_connections = parameters.get("all_connections", [])

# 1) define the simulation components

prob = om.Problem(reports=OPENMDAO_REPORTS)

# add groups

groups = {}

if "Groups" in parameters:

for group in parameters["Groups"]:

name = reformat_compname(group["name"])

kwargs = group.get("kwargs", {})

groups[name] = prob.model.add_subsystem(

name,

om.Group(),

**kwargs,

)

if "solvers" in group:

for solver in group["solvers"]:

if solver["type"] == "nonlinear_solver":

groups[name].nonlinear_solver = OM_DEFAULTS["nonlinear_solver"][

"class"

](**OM_DEFAULTS["nonlinear_solver"]["kwargs"])

solver_obj = groups[name].nonlinear_solver

elif solver["type"] == "linear_solver":

groups[name].linear_solver = OM_DEFAULTS["linear_solver"][

"class"

](**OM_DEFAULTS["linear_solver"]["kwargs"])

solver_obj = groups[name].nonlinear_solver

else:

raise ValueError(

f"Solver of type {solver['type']} is not implemented."

)

if "options" in solver:

for option, val in solver["options"].items():

if option in ["iprint", "maxiter"]:

solver_obj.options[option] = int(val)

else:

solver_obj.options[option] = val

# add components

def get_comp_by_name(name, objs: dict):

comp_type_lookup = {

"ExplicitComponents": OMexplicitComp,

"ImplicitComponents": OMimplicitComp,

}

for key, obj in objs.items():

filtered = [comp_obj for comp_obj in obj if comp_obj["name"] == name]

if filtered:

return [comp_type_lookup[key], filtered[0]]

return OMexplicitComp, None # default

model_lookup = {}

for component in workflow:

# defaults

kwargs = {}

fd_step = 0.1

model = prob.model

has_compute_partials = True # set this to False if fd gradients should be used

objs = {

k: parameters[k]

for k in ["ExplicitComponents", "ImplicitComponents"]

if k in parameters

}

comp_type, comp_obj = get_comp_by_name(component, objs)

if comp_obj:

kwargs = comp_obj.get("kwargs", kwargs)

fd_step = comp_obj.get("fd_step", fd_step)

has_compute_partials = comp_obj.get(

"has_compute_partials", has_compute_partials

)

model = groups.get(comp_obj.get("group"), model)

model_lookup[component] = model

model.add_subsystem(

reformat_compname(component),

comp_type(

compname=component,

fd_step=fd_step,

has_compute_partials=has_compute_partials,

),

**kwargs,

)

if "ExecComps" in parameters and parameters["ExecComps"]:

for component in parameters["ExecComps"]:

prob.model.add_subsystem(

reformat_compname(component["name"]),

om.ExecComp(component["exprs"]),

**component["kwargs"],

)

# 2) define the component connections

def get_var_str(c, name):

return f"{reformat_compname(c)}.{name.replace('.','-')}"

for connection in all_connections:

if connection["type"] == "design":

prob.model.connect(

get_var_str(connection["origin"], connection["name_origin"]),

get_var_str(connection["target"], connection["name_target"]),

)

if parameters["driver"]["type"] == "optimisation":

# 3) setup the optimisation driver options

prob.driver = om.ScipyOptimizeDriver()

prob.driver.options["optimizer"] = parameters["optimizer"]

prob.driver.options["maxiter"] = parameters["max_iter"]

prob.driver.options["tol"] = parameters["tol"]

prob.driver.opt_settings["disp"] = parameters["disp"]

prob.driver.options["debug_print"] = parameters["debug_print"]

if "approx_totals" in parameters and parameters["approx_totals"]:

# ensure FD gradients are used

prob.model.approx_totals(

method="fd", step=parameters["fd_step"], form=None, step_calc=None

)

elif parameters["driver"]["type"] == "doe":

# 3) alternative: setup a design of experiments

levels = parameters["driver"]["kwargs"].get("levels", 2)

if isinstance(levels, float): # All have the same number of levels

levels = int(levels)

elif isinstance(levels, dict): # Different DVs have different number of levels

levels = {k: int(v) for k, v in levels.items()}

prob.driver = DOEDriver(

om.FullFactorialGenerator(levels=levels),

reset_vars=parameters["driver"]["kwargs"].get("reset_vars", {}),

store_case_data=parameters["driver"]["kwargs"].get("store_case_data", {}),

store_parameters=parameters["driver"]["kwargs"].get("store_parameters", {}),

run_folder=run_folder,

)

# 4) add design variables

if "input_variables" in parameters:

for var in parameters["input_variables"]:

upper = var["upper"]

lower = var["lower"]

if "component" in var:

comp_obj = reformat_compname(var["component"])

prob.model.add_design_var(

f"{comp_obj}.{var['name'].replace('.', '-')}",

lower=lower,

upper=upper,

)

else:

prob.model.add_design_var(

var["name"].replace(".", "-"), lower=lower, upper=upper

)

val_default = var.get("value", lower)

prob.model.set_input_defaults(

var["name"].replace(".", "-"), val_default

)

# 5) add an objective and constraints

if "output_variables" in parameters:

for var in parameters["output_variables"]:

comp_obj = reformat_compname(var["component"])

name = f"{comp_obj}.{var['name'].replace('.', '-')}"

# set scaling from parameter input file

scaler = var.get("scaler", None)

adder = var.get("adder", None)

if var["type"] == "objective":

prob.model.add_objective(name, scaler=scaler, adder=adder)

elif var["type"] == "constraint":

lower = var.get("lower", None)

upper = var.get("upper", None)

prob.model.add_constraint(

name, lower=lower, upper=upper, scaler=scaler, adder=adder

)

prob.setup() # required to generate the n2 diagram

print("OpenMDAO problem setup completed.")

if "visualise" in parameters and "n2_diagram" in parameters["visualise"]:

# save n2 diagram in html format

om.n2(

prob,

outfile=str(run_folder / "n2.html"),

show_browser=False,

)

if parameters["driver"]["type"] == "optimisation":

dict_out = run_optimisation(prob, parameters, run_folder)

# elif parameters["driver"]["type"] == "check_partials":

# dict_out = run_check_partials(prob, parameters)

# elif parameters["driver"]["type"] == "check_totals":

# dict_out = run_check_totals(prob, parameters)

elif parameters["driver"]["type"] == "doe":

nb_threads = int(parameters["driver"].get("nb_threads", 1))

dict_out = run_doe(prob, parameters, run_folder, nb_threads=nb_threads)

# elif parameters["driver"]["type"] == "post":

# dict_out = run_post(prob, parameters)

else:

with open(run_folder / "trim_convergence.log", "w") as f:

with redirect_stdout(f):

prob.run_model()

dict_out = {}

message = f"{datetime.now().strftime('%Y%m%d-%H%M%S')}: OpenMDAO compute completed."

print(message)

if dict_out:

outputs["design"] = dict_out

return {"message": message, "outputs": outputs}

def run_optimisation(prob, parameters, run_folder):

# 6) add a data recorder to the optimisation problem

r_name = str(

run_folder

/ (

"om_problem_recorder_"

+ datetime.now().strftime("%Y%m%d-%H%M%S")

+ ".sqlite"

)

)

r = om.SqliteRecorder(r_name)

prob.driver.add_recorder(r)

prob.driver.recording_options["record_derivatives"] = True

# setup the problem again

prob.setup()

if "visualise" in parameters and "scaling_report" in parameters["visualise"]:

# NOTE: running the model can generate large large amounts of stored data in orchestrator, which

# can cause prob.setup() to fail if it is called again, so only execute

# prob.run_model() after all setup has been completed

try:

with open(run_folder / "scaling_report.log", "w") as f:

with redirect_stdout(f):

prob.run_model()

prob.driver.scaling_report(

outfile=str(run_folder / "driver_scaling_report.html"),

title=None,

show_browser=False,

jac=True,

)

except Exception as e:

with open(run_folder / "run_driver.log", "w") as f:

with redirect_stdout(f):

tb = traceback.format_exc()

print(f"OpenMDAO prob.run_model() exited with error: {e}")

print(tb)

raise ValueError(

"OpenMDAO prob.run_model() error. Check outputs/run_driver.log for details."

)

# 7) execute the optimisation

try:

with open(run_folder / "run_driver.log", "w") as f:

with redirect_stdout(f):

prob.run_driver()

except Exception as e:

with open(run_folder / "run_driver.log", "w") as f:

with redirect_stdout(f):

tb = traceback.format_exc()

print(f"run driver exited with error: {e}")

print(tb)

raise ValueError(

"OpenMDAO Optimisation error. Check outputs/run_driver.log for details."

)

opt_output = {}

# print("Completed model optimisation - solution is: \n inputs= (")

for var in parameters["input_variables"]:

name = var["name"]

# print(

# f"{comp}.{name}: "

# + str(prob.get_val(f"{comp}.{name.replace('.', '-')}"))

# + " "

# )

if "component" in var:

comp = var["component"]

opt_output[f"{comp}.{name}"] = prob.get_val(

f"{reformat_compname(comp)}.{name.replace('.', '-')}"

).tolist()

else:

opt_output[name] = prob.get_val(name.replace(".", "-")).tolist()

# print("), \n outputs = (")

for var in parameters["output_variables"]:

comp = var["component"]

name = var["name"]

# print(

# f"{comp}.{name}: "

# + str(prob.get_val(f"{comp}.{name.replace('.', '-')}"))

# + " "

# )

opt_output[f"{comp}.{name}"] = prob.get_val(

f"{reformat_compname(comp)}.{name.replace('.', '-')}"

).tolist()

# print(")")

print(opt_output)

if "visualise" in parameters and "plot_history" in parameters["visualise"]:

post_process_optimisation(parameters, run_folder, r_name)

return opt_output

def run_doe(prob, parameters, run_folder, nb_threads=1):

# 7) execute the driver in parallel

def run_cases_thread(color):

print(f"Starting thread {color}.")

prob_copy = deepcopy(prob)

print(f"problem id for color {color}: ", id(prob_copy))

# set driver instance properties

prob_copy.driver.nb_threads = nb_threads

prob_copy.driver.color = color

try:

prob_copy.run_driver()

except Exception as e:

print(f"run driver exited with error: {e}")

tb = traceback.format_exc()

return f"OpenMDAO DOE error: {tb}"

print(f"Completed thread {color}.")

with open(run_folder / f"run_driver.log", "w") as f:

with redirect_stdout(f):

with ThreadPoolExecutor(max_workers=nb_threads) as executor:

msgs = executor.map(run_cases_thread, range(nb_threads))

errors = list(msgs)

if errors and errors[0]:

raise ValueError(errors[0])

print("completed all threads")

if "visualise" in parameters and "plot_history" in parameters["visualise"]:

from post import post_process_doe

post_process_doe(

parameters,

run_folder,

files=[f"results_{c}.json" for c in range(nb_threads)],

)

return {}

def reformat_compname(name):

# openmdao doesn't allow "-" character in component names

return name.replace("-", "_")

def post_process_optimisation(

parameters, run_folder, r_name, only_plot_major_iter=True

):

# read database

# Instantiate your CaseReader

cr = om.CaseReader(r_name)

# Isolate "problem" as your source

driver_cases = cr.list_cases("driver", out_stream=None)

# plot the iteration history from the recorder data

inputs_history = {

key: []

for key in [

f"{reformat_compname(var['component'])}.{var['name'].replace('.', '-')}"

for var in parameters["input_variables"]

]

}

outputs_history = {

key: []

for key in [

f"{reformat_compname(var['component'])}.{var['name'].replace('.', '-')}"

for var in parameters["output_variables"]

]

}

for key in driver_cases:

case = cr.get_case(key)

if (only_plot_major_iter and case.derivatives) or not only_plot_major_iter:

# get history of inputs

for key in inputs_history:

inputs_history[key].append(case.outputs[key])

# get history of outputs

for key in outputs_history:

outputs_history[key].append(case.outputs[key])

# plot output in userfriendly fashion

_plot_iteration_histories(

inputs_history=inputs_history,

outputs_history=outputs_history,

run_folder=run_folder,

)

def _plot_iteration_histories(

inputs_history=None, outputs_history=None, run_folder=None

):

# plot input histories

for key in inputs_history:

input_data = inputs_history[key]

input_data = np.array(input_data)

iterations = range(input_data.shape[0])

plt.figure()

for data_series in input_data.T:

plt.plot(iterations, data_series, "-o")

plt.grid(True)

plt.title(key)

plt.savefig(str(run_folder / (key + ".png")))

# plot output histories

for key in outputs_history:

output_data = outputs_history[key]

output_data = np.array(output_data)

iterations = range(output_data.shape[0])

plt.figure()

for data_series in output_data.T:

plt.plot(iterations, data_series, "-o")

plt.grid(True)

plt.title(key)

plt.savefig(str(run_folder / (key + ".png")))

plt.show()

class DOEDriver(om.DOEDriver):

def __init__(

self,

generator=None,

reset_vars: dict = None,

store_case_data: list = None,

store_parameters: dict = None,

run_folder: Path = None,

**kwargs,

):

self.reset_vars = reset_vars

self.cases_store = []

self.store_case_data = store_case_data

self.store_parameters = store_parameters

self.run_folder = run_folder

self.nb_threads = 1

self.color = 0

super().__init__(generator=generator, **kwargs)

def run(self):

"""

Generate cases and run the model for each set of generated input values.

Returns

-------

bool

Failure flag; True if failed to converge, False is successful.

"""

self.iter_count = 0

self._quantities = []

# set driver name with current generator

self._set_name()

# Add all design variables

dv_meta = self._designvars

self._indep_list = list(dv_meta)

# Add all objectives

objs = self.get_objective_values()

for name in objs:

self._quantities.append(name)

# Add all constraints

con_meta = self._cons

for name, _ in con_meta.items():

self._quantities.append(name)

for case in self._parallel_generator(self._designvars, self._problem().model):

print(f"Starting case on thread {self.color}.")

self._custom_reset_variables()

self._run_case(case)

self.iter_count += 1

self._custom_store_to_json()

return False

def _custom_reset_variables(self):

# reset the initial variable guesses

for k, v in self.reset_vars.items():

self._problem()[k] = v

def _custom_store_to_json(self):

# store the outputs to the json database

self.cases_store.append(

{

**self.store_parameters,

**{

k.split(".")[-1]: self._problem()[k][0]

for k in self.store_case_data

},

}

)

# dump to json file

fname = f"results_{self.color}.json"

with open(self.run_folder / fname, "w", encoding="utf-8") as f:

json.dump(self.cases_store, f)

def _parallel_generator(self, design_vars, model=None):

"""

Generate case for this thread.

Parameters

----------

design_vars : dict

Dictionary of design variables for which to generate values.

model : Group

The model containing the design variables (used by some generators).

Yields

------

list

list of name, value tuples for the design variables.

"""

size = self.nb_threads

color = self.color

generator = self.options["generator"]

for i, case in enumerate(generator(design_vars, model)):

if i % size == color:

yield case

if __name__ == "__main__":

with open("open-mdao-driver/parameters.json", "r") as f:

parameters = json.load(f)

parameters["all_connections"] = [

{

"origin": "vspaero",

"name_origin": "CL",

"target": "trim",

"name_target": "CL",

"type": "design",

},

{

"origin": "vspaero",

"name_origin": "CMy",

"target": "trim",

"name_target": "CMy",

"type": "design",

},

]

parameters["workflow"] = ["vspaero", "trim"] # defined by controller

parameters["outputs_folder_path"] = "outputs" # defined by component generic api

compute(

inputs={},

outputs={"design": {}},

partials=None,

options=None,

parameters=parameters,

)

numpy==1.23.5

openmdao==3.28.0

matplotlib==3.7.0

fluids==1.0.22

pandas==1.5.3

""" Optimisation Component classes for OpenMDAO and associated utilities."""

import numpy as np

import openmdao.api as om # type: ignore

from component_api2 import call_compute, call_setup

import traceback

class OMexplicitComp(om.ExplicitComponent):

"""standard component that follows the OM conventions"""

def __init__(self, compname, fd_step, has_compute_partials=True):

super().__init__()

self.compname = compname

self.get_grads = False

self.iter = 0

self.partial_dict = None

self.fd_step = fd_step

self._has_compute_partials = has_compute_partials # overrides parent class attribute with user defined parameter

def setup(self):

message = {"component": self.compname}

_, component_dict = call_setup(message)

inputs = component_dict["input_data"]["design"]

outputs = component_dict["output_data"]["design"]

# initialise the inputs

if inputs:

for variable in inputs:

self.add_input(variable.replace(".", "-"), val=inputs[variable])

# initialise the outputs

if outputs:

for variable in outputs:

self.add_output(variable.replace(".", "-"), val=outputs[variable])

def setup_partials(self):

# Get the component partial derivative information

message = {"component": self.compname}

_, component_dict = call_setup(message)

if "partials" in component_dict and component_dict["partials"]:

self.partial_dict = component_dict["partials"]

for resp, vars in self.partial_dict.items():

for var, vals in vars.items():

self.declare_partials(

resp.replace(".", "-"), var.replace(".", "-"), **vals

)

else:

# calculate all paritials using finite differencing

self.declare_partials("*", "*", method="fd", step=self.fd_step)

def compute(self, inputs, outputs, discrete_inputs=None, discrete_outputs=None):

print("Calling compute.")

# calculate the outputs

# Note: transform all np.ndarrays into nested lists to allow formatting to json

input_dict = {"design": reformat_inputs(inputs._copy_views())}

message = {

"component": self.compname,

"inputs": input_dict,

"get_grads": False,

"get_outputs": True,

}

print("message: \n", str(message))

try:

_, data = call_compute(message)

if not "outputs" in data:

raise ValueError(f"Error: Compute output missing - output was: {data}.")

except Exception as e:

print(f"Compute of {self.compname} failed, input data was: {str(message)}")

tb = traceback.format_exc()

print(tb)

raise ValueError(

f"OM Explicit component {self.compname} compute error: " + tb

)

val_outputs = data["outputs"]["design"]

# OpenMDAO doesn't like the outputs dictionary to be overwritten, so

# assign individual outputs one at a time instead

for output in outputs:

outputs[output] = val_outputs[output.replace("-", ".")]

def compute_partials(self, inputs, J):

"""Jacobian of partial derivatives."""

print("Calling compute_partials.")

self.iter += 1

input_dict = reformat_inputs(inputs._copy_views())

message = {

"component": self.compname,

"inputs": input_dict,

"get_grads": True,

"get_outputs": False,

}

print("message: \n", str(message))

try:

_, data = call_compute(message)

if not "partials" in data:

raise ValueError(

f"Error: Compute partial derivatives missing - output was: {data}."

)

self.partial_dict = data["partials"]

except Exception as e:

print(

f"Compute partials of {self.compname} failed, input data was: {str(message)}"

)

tb = traceback.format_exc()

print(tb)